Sunon EC fans as a spin-off of the widely used AC axial fan

You might have heard the phrase “Stagnation means decline.” on multiple occasions, but probably not in relation to fans and thermal management. But it’s a relevant phrase in thermal management applications. Creating air flow with the help of axial fans is the most common used heat dissipation method. Fans that stop spinning don’t move air, cannot dissipate heat, and compromise the longevity of the electronic components they are supposed to cool.

So, motion is critical in the world of heat dissipation. And with today’s amount of applications, achieving this efficiently is almost a form of art. In this article we take a closer look at electronically commutated driven industrial fans, merging the advantages of AC and DC motor technology.

Cooling industrial electronics with fans driven by AC-power

Axial fans driven by alternating current voltages are common in heavy-duty applications. They do not require a converter and can easily be connected to the AC power supply. Sounds simple, and for the most part it is, so what’s the catch? Well, just like other components with moving parts, axial fans are sensitive to wear, and AC powered models are less efficient than their DC counterparts.

So even this is a well-established cooling method, there is still room for improvement. This is where the EC Series from SUNON comes in place, combining the best of both worlds: fans with highly efficient brushless DC motors and speed control functions on an AC voltage supply. Let’s take a spin!

EC, the solution to make AC fans more sustainable

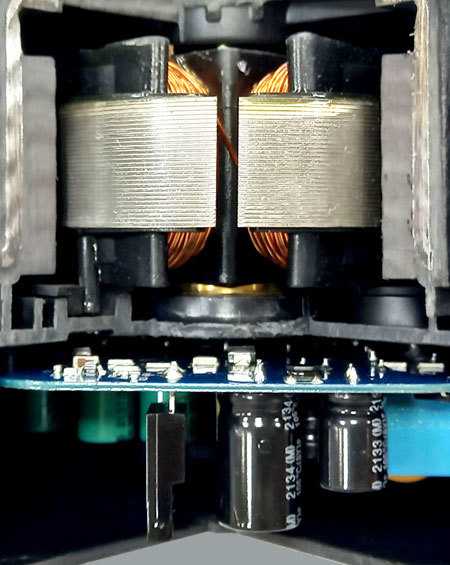

Electronically commutated fans, EC fans for short, is a relatively new fan motor technology. The motor is powered with an AC voltage supply and uses an integrated converter to deliver DC voltage to the brushless motor. This all-in-one solution of power supply, converter, and motor, takes full advantage from the benefits of common DC fans like the ones in your laptop or gaming console.

Besides lowering the energy demand with up to 80% compared to default AC models, a brushless DC motor runs significantly cooler, which drastically increases the lifespan and operating temperature of the unit. A direct current voltage supply is also ideal to regulate the RPM of the impeller of the fan. EC motors also avoid sparking and potential electromagnetic interference that occurs in brushed motors. Another positive aspect is that EC fans generate less noise, a welcome advantage for domestic appliances, office equipment and commercial applications.

Overall, thermal solutions like the SUNON EC series bring significant benefits to the environment of the system designer, manufacturer and end user.

More information about Sunon EC fans?

Jonathan Muszynski

Sales

Don't neglect the 'Performance per Watt'-ratio in your design

Lowering energy consumption without sacrificing on system performances is one of the challenges for the manufacturing industry. Expelling heat from electronics with as little energy as possible is often neglected by system designers when looking at total energy consumption.

Replacing a standard industrial AC fan with a similar performing SUNON EC model can reduce power consumption with more than 15 Watts per fan. In a 24/7 use case scenario, such as server cabinets in data centers, this reduces the annual energy consumption with more than 130 kWh per fan. When you consider that these types of applications have multiple fans operational, the overall energy savings are much higher, even if the application is on for a shorter period of time.

Vertical MagLev motor technology for a low noise cooling experience

For applications that require the quietest fans possible, such as household appliances or equipment for medical applications, SUNON gives you the option to apply EC fans with the vertical aligned and stabilized MagLev motor technology.

Axial fans equipped with this drive system let the rotor of the fan stably swivel on a magnetically fixed point, making it less sensitive to wobbling and shaking. This impeller stabilization reduces friction between the shaft and the VAPO bearing, resulting in low noise, low vibration and a longer lifespan.

Heavy-duty variations for demanding environments

EC fans are built to deliver a consistent airflow for cooling entire systems and individual components. The high performance per Watt ratio fans are also available for more demanding applications where stricter safety requirements are prescribed for electrical products and protective systems.

Various IP55, IP68 and ATEX models are included in the SUNON portfolio, so it is possible to replace outdated AC fans used in humid, dusty or potentially explosive atmospheres with better performing EC counterparts.

Using SUNON axial fans in your builds or product assemblies

Reliable heat dissipation is vital for the lifespan and performance of machines and systems, especially in industrial and hazardous environments. And with today’s number of manufacturers and options, we understand it can become blurry in front of you when you research all the possibilities.

Our engineers are familiar with these challenges and have experience in selecting appropriate cooling solutions for all kinds of industrial and electronic systems. They are here to assist you in this phase of your products’ design and manufacturing process, from component selection or custom builds, all the way to delivery and evaluating product samples. Share your application story with our team and we will figure out the best thermal management solution together.

And what if industrial fans are not sufficient? Then we will have a look at our other thermal solutions, such as heatsinks, vapor chambers and liquid cold plates.